TECH TIP:

Zone Level Moisture Load - Part Two

By Jerry Sipes - Ph.D., P.E, Vice President of Engineering

In my previous Tech Tip, I went through an analysis of moisture loads for a boardroom with overhead mixing air distribution. In this Tech Tip,

I will go through a similar analysis for the application of active chilled beams, overhead mixing and displacement ventilation for a boardroom,

private office and classroom. For the detailed steps in the moisture analysis, I refer you to the previous Tech Tip (Price Engineering Update – Volume 19)

or the ASHRAE Humidity Control Design Guide.

The goal of this Tech Tip is to discuss the difference in the entering air moisture content to control the various spaces with the different types

of air distribution and their associated supply air volumes. This discussion is only for the identified spaces, not an entire building. Please note

that these results are not optimized as they would be when the entire building is analyzed.

As a reminder, there are eight types of moisture gains to the occupied space and each must be analyzed for the specific building construction,

occupancy and ambient climatic conditions.

-

Ventilation load: This is typically the largest source of moisture load since the ventilation air is from outdoors.

The moisture content in the ventilation air depends on the outdoor conditions and will vary over the year as the climatic conditions change.

-

Infiltration load: This is moisture that is transported through the building façade into the occupied space through wall materials,

windows and imperfections in the construction. This load is often magnified by wind driven pressure differentials. The age of the

building may impact the amount of infiltration with older construction practices and materials having a higher potential for moisture

and air movement across the building façade.

-

Occupant generated load: Occupants continually give off moisture through respiration and evaporation.

Additionally, their clothing may transport moisture into the occupied space due to weather events such as rain.

-

Diffusion load: Moisture is transported through the building material due to porosity in the material.

A gauge of the potential for diffusion load is referred to as material permeance.

- Internal load: This includes building features such as fountains, swimming pools, kitchens, etc

-

Windows and doors: Doors and operable windows can add significant moisture loads depending upon occupant

behavior (i.e. leaving windows open at night).

- Wet surfaces: These can be generated by cleaning tables in dining areas, mopping hard surfaces, etc.

-

Other sources: Additional potential moisture sources include carpet cleaning, products or materials

delivery (cartons, etc.) that have absorbed moisture content.

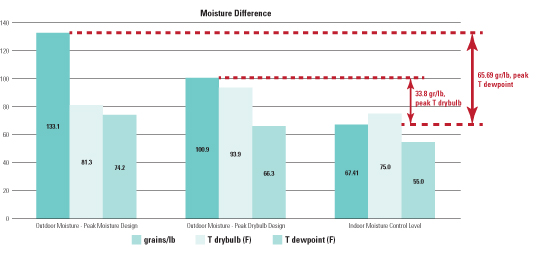

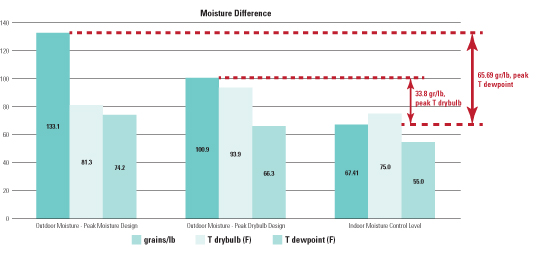

This comparison will be using Atlanta Outdoor Design Conditions as shown in Figure 1.

Figure 1: Atlanta Outdoor Design Conditions (ASHRAE 2013 Handbook of Fundamentals, Chapter 14)

All room constructions will have an exterior wall with a leak rate of 0.1 cfm/ft2 (tight construction) (ASHRAE Humidity Control Design Guide, Figure 11.5).

Occupants are considered to be seated and moderately active, generating 0.19 lb/h of moisture each (ASHRAE Humidity Control Design Guide, Figure 11.5).

Vapor permeance is considered to be minor compared to the outside air infiltration rate. This is typically a good assumption unless the building is new and the

concrete is still emitting water vapor as it continues to cure.

The volume of air from infiltration is considered small compared to the ventilation air volume. This allows an easier solution to the equations listed below.

If the infiltration air volume is significant, the solution is iterative.

For the load calculations / air volumes for the application of overhead mixing, displacement ventilation and active chilled beams, the reader is referred to

the Price Engineer’s HVAC Handbook.

The moisture content of the supply air is based on absorbing the space moisture load using the supply air volume determined by the loads and type of air

distribution used.

Using ASHRAE Standard 55-2013, Thermal Conditions for Human Occupancy as a guide, the space humidity is set to a maximum of 0.012 lbw/lbda (84 gr/lbda).

The space set point temperature is 75℉. There are no other sources of moisture in the spaces. All calculations used an elevation of sea level.

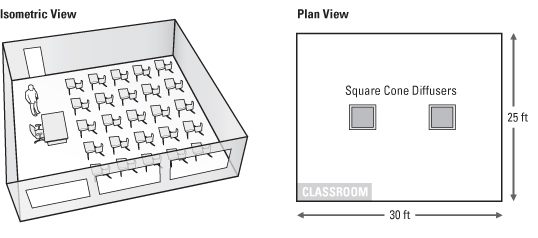

Equations used for this analysis:

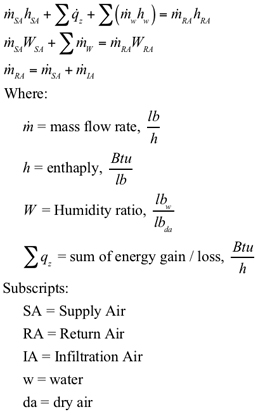

Boardroom

See Figure 2, Table 1 and Table 2 for dimensions, parameters and supply air comparisons. It is interesting to note that displacement ventilation

allows the supply air to have a higher moisture content than overhead ventilation or active chilled beams. I must point out that this is one space

in the entire building and depending upon the climatic zone and the types of occupied spaces, the displacement ventilation may offer extended periods of

free cooling compared to the mixing systems.

Table 1: Boardroom Example Parameters

Room Set-Point (cooling)

75F

External Wall Area (floor to floor)

672 SF

Occupant/Equipment Sensible Load

4,496 BTUH

Lighting Sensible Load

3,928 BTUH

Shell Gain (cooling mode)

10,752 BTUH

Total Sensible Gain (cooling mode)

19,176 BTUH (33.3 BTUH/SF)

Desired Maximum Zone Moisture Content

84 grains/lb

Mixed Min Ventilation per ASHRAE 62.1

115 CFM

Displacement Min Vent per ASHRAE 62.1

95 CFM

Estimated Volume of water added to space from occupants

3.0 lbw/h

Estimated volume of water added due to infiltration, diffusion, & internal loads

2.8 lbw/h

Total Volume of water to remove with supply air

5.8 lbw/h

Parameter:

# Occupants

Value:

16

Parameter:

Room Set-point (cooling)

Value:

75F

Parameter:

Floor Area

Value:

576 SF

Parameter:

External Wall Area (floor to floor)

Value:

672 SF

Parameter:

Occupant/Equipment Sensible Load

Value:

4,496 BTUH

Parameter:

Lighting Sensible Load

Value:

3,928 BTUH

Parameter:

Shell Gain (cooling mode)

Value:

10,752 BTUH

Parameter:

Total Sensible Gain (cooling mode)

Value:

19,176 BTUH (33.3 BTUH/SF)

Parameter:

Desired Maximm Zone Moisture Content

Value:

84 grains / lb

Parameter:

Mixed Min Ventilation per ASHRAE 62.1

Value:

115 CFM

Parameter:

Displacement Min Vent per ASHRAE 62.1

Value:

95 CFM

Parameter:

Estimated volume of water added to space from occupants

Value:

3.0 lbw/h

Parameter:

Estimated volume of water added due to infiltration, diffusion, & internal loads

Value:

2.8 lbw/h

Parameter:

Total volume of water to remove with supply air

Value:

5.8 lbw/h

Table 2: Boardroom Supply Air Method Comparison

Supply Air Temperature, F

55

63

75

Supply Water Temperature, F

N/A

N/A

64

Zone Dew Point, F

62.2

62.2

62.2

Zone/Return Air Temperature, F

75

89 (estimated)

75

Temperature difference between head and feet, F

Minimal

5.2

Minimal

Estimated ventilation effectiveness

1.0

1.8

1.0

Supply Air Volume, cfm

887

673

270

Supply Air Gr/lb

54.6

70.4

50.1

Supply Air Enthalpy, BTU/lb

21.7

26.1

21.0

Return Air, Gr/lb

64.9

84.0

84.0

Return Air Enthalpy, BTU/lb

28.1

34.6

31.1

For information on supply air volume calculation, product selection and product placement see:

1. Price Engineer’s HVAC Handbook, Chapter 9

2. Price Engineer’s HVAC Handbook, Chapters 15 - 16 and Price Displacement Room Designer Software

3. Price Engineer’s HVAC Handbook, Chapter 19 and Price Beams Room Designer Software

Parameter:

Supply Air Temperature, F

Mixing Ventilation:

55

Displacement Ventilation:

63

Active Chilled Beams:

75

Parameter:

Supply Water Temperature, F

Mixing Ventilation:

N/A

Displacement Ventilation:

N/A

Active Chilled Beams:

64

Parameter:

Zone Dew Point, F

Mixing Ventilation:

62.2

Displacement Ventilation:

62.2

Active Chilled Beams:

62.2

Parameter:

Zone/Return Air Temperature, F

Mixing Ventilation:

75

Displacement Ventilation:

89 (estimated)

Active Chilled Beams:

75

Parameter:

Temperature difference between head and feet, F

Mixing Ventilation:

Minimal

Displacement Ventilation:

5.2

Active Chilled Beams:

Minimal

Parameter:

Estimated ventilation effectiveness

Mixing Ventilation:

1.0

Displacement Ventilation:

1.8

Active Chilled Beams:

1.0

Parameter:

Supply Air Volume, cfm

Mixing Ventilation:

887

Displacement Ventilation:

673

Active Chilled Beams:

270

Parameter:

Supply Air Gr/lb

Mixing Ventilation:

54.6

Displacement Ventilation:

70.4

Active Chilled Beams:

50.1

Parameter:

Supply Air Enthalpy, BTU/lb

Mixing Ventilation:

21.7

Displacement Ventilation:

26.1

Active Chilled Beams:

21.0

Parameter:

Return Air, Gr/lb

Mixing Ventilation:

64.9

Displacement Ventilation:

84.0

Active Chilled Beams:

84.0

Parameter:

Return Air Enthalpy, BTU/lb

Mixing Ventilation:

28.1

Displacement Ventilation:

34.6

Active Chilled Beams:

31.1

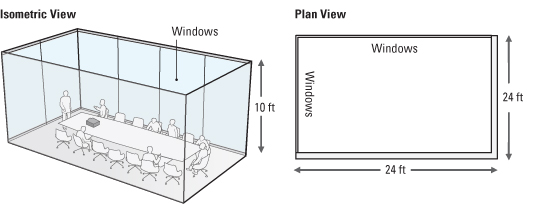

Private Office

See Figure 3, Table 3 and Table 4 for dimensions, parameters and supply air comparisons. In this single occupancy office example,

due to the low loads, there is not as much variance in the supply air volume for the overhead mixing and displacement ventilation systems.

The active chilled beam system does offer a significant reduction in supply air volume, but requires the driest supply air of the three compared,

or an increase in the supply air volume. Please note that the active chilled beam systems is using a neutral air temperature due to the small loads.

Table 3: Single Occupancy Office Example Parameters

Room Set-Point (cooling)

75F

External Wall Area (floor to floor)

168 SF

Occupant/Equipment Sensible Load

800 BTUH

Lighting Sensible Load

825 BTUH

Shell Gain (cooling mode)

840 BTUH

Total Sensible Gain (cooling mode)

2465 BTUH (20.5 BTUH/SF)

Desired Maximum Zone Moisture Content

84 grains/lb

Mixed Min Ventilation per ASHRAE 62.1

17.2 CFM

Displacement Min Vent per ASHRAE 62.1

14.3 CFM

Estimated Volume of water added to space from occupants

0.4 lbw/h

Estimated volume of water added due to infiltration, diffusion, & internal loads

0.7 lbw/h

Total Volume of water to remove with supply air

1.1 lbw/h

Parameter:

# Occupants

Value:

2

Parameter:

Room Set-point (cooling)

Value:

75F

Parameter:

Floor Area

Value:

120 SF

Parameter:

External Wall Area (floor to floor)

Value:

168 SF

Parameter:

Occupant/Equipment Sensible Load

Value:

825 BTUH

Parameter:

Lighting Sensible Load

Value:

825 BTUH

Parameter:

Shell Gain (cooling mode)

Value:

840 BTUH

Parameter:

Total Sensible Gain (cooling mode)

Value:

2465 BTUH (20.5 BTUH/SF)

Parameter:

Desired Maximm Zone Moisture Content

Value:

84 grains / lb

Parameter:

Mixed Min Ventilation per ASHRAE 62.1

Value:

17.2 CFM

Parameter:

Displacement Min Vent per ASHRAE 62.1

Value:

14.3 CFM

Parameter:

Estimated volume of water added to space from occupants

Value:

0.4 lbw/h

Parameter:

Estimated volume of water added due to infiltration, diffusion, & internal loads

Value:

0.7 lbw/h

Parameter:

Total volume of water to remove with supply air

Value:

1.1 lbw/h

Table 4: Single Occupancy Office Supply Air Method Comparison

Supply Air Temperature, F

55

63

70

Supply Water Temperature, F

N/A

N/A

65

Zone Dew Point, F

34.8

37

61.5

Zone/Return Air Temperature, F

75

86 (estimated)

75

Temperature difference between head and feet, F

Minimal

4.6

Minimal

Estimated ventilation effectiveness

1.0

1.7

1.0

Supply Air Volume, cfm

114

98

50

Supply Air Gr/lb

60.1

57.7

48.1

Supply Air Enthalpy, BTU/lb

22.6

24.1

24.3

Return Air, Gr/lb

75

75

82

Return Air Enthalpy, BTU/lb

29.7

32.4

30.8

For information on supply air volume calculation, product selection and product placement see:

1. Price Engineer’s HVAC Handbook, Chapter 9

2. Price Engineer’s HVAC Handbook, Chapters 15 - 16 and Price Displacement Room Designer Software

3. Price Engineer’s HVAC Handbook, Chapter 19 and Price Beams Room Designer Software

Parameter:

Supply Air Temperature, F

Mixing Ventilation:

55

Displacement Ventilation:

63

Active Chilled Beams:

70

Parameter:

Supply Water Temperature, F

Mixing Ventilation:

N/A

Displacement Ventilation:

N/A

Active Chilled Beams:

65

Parameter:

Zone Dew Point, F

Mixing Ventilation:

34.8

Displacement Ventilation:

37

Active Chilled Beams:

61.5

Parameter:

Zone/Return Air Temperature, F

Mixing Ventilation:

75

Displacement Ventilation:

86 (estimated)

Active Chilled Beams:

75

Parameter:

Temperature difference between head and feet, F

Mixing Ventilation:

Minimal

Displacement Ventilation:

4.6

Active Chilled Beams:

Minimal

Parameter:

Estimated ventilation effectiveness

Mixing Ventilation:

1.0

Displacement Ventilation:

1.7

Active Chilled Beams:

1.0

Parameter:

Supply Air Volume, cfm

Mixing Ventilation:

114

Displacement Ventilation:

98

Active Chilled Beams:

50

Parameter:

Supply Air Gr/lb

Mixing Ventilation:

60.1

Displacement Ventilation:

57.7

Active Chilled Beams:

48.1

Parameter:

Supply Air Enthalpy, BTU/lb

Mixing Ventilation:

22.6

Displacement Ventilation:

24.1

Active Chilled Beams:

24.3

Parameter:

Return Air, Gr/lb

Mixing Ventilation:

75

Displacement Ventilation:

75

Active Chilled Beams:

82

Parameter:

Return Air Enthalpy, BTU/lb

Mixing Ventilation:

29.7

Displacement Ventilation:

32.4

Active Chilled Beams:

30.8

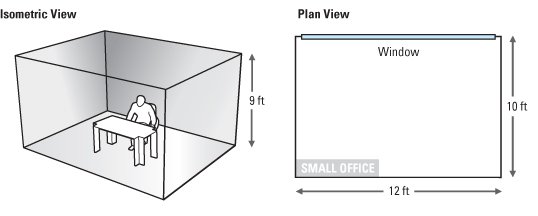

Classroom

See Figure 4, Table 5 and Table 6 for dimensions, parameters and supply air comparisons. This space is a great application for active chilled beams as the volume of supply air nearly matches the volume of required outside air and the moisture content of the overhead mixing, displacement ventilation and active chilled beam systems are very similar.

These examples are for a zone level analysis and show some non-optimized selections. The entire building should be investigated to determine the proper moisture content of the supply air and then the individual zones can be sized for the selected method of air distribution.

Table 5: Classroom Example Parameters

Room Set-Point (cooling)

75F

External Wall Area (floor to floor)

420 SF

Occupant/Equipment Sensible Load

10,924 BTUH

Lighting Sensible Load

5,156 BTUH

Shell Gain (cooling mode)

3,570 BTUH

Total Sensible Gain (cooling mode)

19,650 BTUH (26.2 BTUH/SF)

Desired Maximum Zone Moisture Content

84 grains/lb

Mixed Min Ventilation per ASHRAE 62.1

490 CFM

Displacement Min Vent per ASHRAE 62.1

408 CFM

Estimated Volume of water added to space from occupants

7.6 lbw/h

Estimated volume of water added due to infiltration, diffusion, & internal loads

1.8 lbw/h

Total Volume of water to remove with supply air

9.4 lbw/h

Parameter:

# Occupants

Value:

40

Parameter:

Room Set-point (cooling)

Value:

75F

Parameter:

Floor Area

Value:

750 SF

Parameter:

External Wall Area (floor to floor)

Value:

420 SF

Parameter:

Occupant/Equipment Sensible Load

Value:

10,924 BTUH

Parameter:

Lighting Sensible Load

Value:

5,156 BTUH

Parameter:

Shell Gain (cooling mode)

Value:

3,570 BTUH

Parameter:

Total Sensible Gain (cooling mode)

Value:

19,650 BTUH (26.2 BTUH/SF)

Parameter:

Desired Maximm Zone Moisture Content

Value:

84 grains / lb

Parameter:

Mixed Min Ventilation per ASHRAE 62.1

Value:

490 CFM

Parameter:

Displacement Min Vent per ASHRAE 62.1

Value:

408 CFM

Parameter:

Estimated volume of water added to space from occupants

Value:

7.6 lbw/h

Parameter:

Estimated volume of water added due to infiltration, diffusion, & internal loads

Value:

1.8 lbw/h

Parameter:

Total volume of water to remove with supply air

Value:

9.4 lbw/h

Table 6: Classroom Supply Air Method Comparison

Supply Air Temperature, F

55

63

55

Supply Water Temperature, F

N/A

N/A

58

Zone Dew Point, F

57.2

59.1

60.8

Zone/Return Air Temperature, F

75

86 (estimated)

75

Temperature difference between head and feet, F

Minimal

5.3

Minimal

Estimated ventilation effectiveness

1.0

2.2

1.0

Supply Air Volume, cfm

909

784

550

Supply Air Gr/lb

54

51.4

53.5

Supply Air Enthalpy, BTU/lb

21.6

23.1

21.5

Return Air, Gr/lb

70

70

80

Return Air Enthalpy, BTU/lb

28.9

31.6

30.5

For information on supply air volume calculation, product selection and product placement see:

1. Price Engineer’s HVAC Handbook, Chapter 9

2. Price Engineer’s HVAC Handbook, Chapters 15 - 16 and Price Displacement Room Designer Software

3. Price Engineer’s HVAC Handbook, Chapter 19 and Price Beams Room Designer Software

Parameter:

Supply Air Temperature, F

Mixing Ventilation:

55

Displacement Ventilation:

63

Active Chilled Beams:

55

Parameter:

Supply Water Temperature, F

Mixing Ventilation:

N/A

Displacement Ventilation:

N/A

Active Chilled Beams:

58

Parameter:

Zone Dew Point, F

Mixing Ventilation:

57.2

Displacement Ventilation:

59.1

Active Chilled Beams:

60.8

Parameter:

Zone/Return Air Temperature, F

Mixing Ventilation:

75

Displacement Ventilation:

86 (estimated)

Active Chilled Beams:

75

Parameter:

Temperature difference between head and feet, F

Mixing Ventilation:

Minimal

Displacement Ventilation:

5.3

Active Chilled Beams:

Minimal

Parameter:

Estimated ventilation effectiveness

Mixing Ventilation:

1.0

Displacement Ventilation:

2.2

Active Chilled Beams:

1.0

Parameter:

Supply Air Volume, cfm

Mixing Ventilation:

909

Displacement Ventilation:

784

Active Chilled Beams:

550

Parameter:

Supply Air Gr/lb

Mixing Ventilation:

54

Displacement Ventilation:

51.4

Active Chilled Beams:

53.5

Parameter:

Supply Air Enthalpy, BTU/lb

Mixing Ventilation:

21.6

Displacement Ventilation:

23.1

Active Chilled Beams:

21.5

Parameter:

Return Air, Gr/lb

Mixing Ventilation:

70

Displacement Ventilation:

70

Active Chilled Beams:

80

Parameter:

Return Air Enthalpy, BTU/lb

Mixing Ventilation:

28.9

Displacement Ventilation:

31.6

Active Chilled Beams:

30.5

For more information on similar topics, please see www.priceindustries.com or the Price Engineer’s HVAC Handbook.