Volume 21 (June 2016) DOWNLOAD PDF

FEATURED ARTICLE:

Room Pressure Monitors: Application In Critical Spaces

By David Enns – Applications Specialist, Price Critical Controls

Room pressure monitors are designed to measure the differential pressure between two spaces and provide a visual indication of the pressure relationship. This pressure relationship is maintained through an offset between the supply and exhaust air of the ventilation system. The visual status indicates to occupants and facility users when the ventilation system is not controlling the pressure. Today’s monitors often employ additional added-value features, such as connectivity to the building management system (BMS) and the ability to monitor temperature and humidity.

In critical spaces like laboratories, pharmacies and isolation rooms, room pressure is paramount to the safety of not only the occupant but the entire building. The critical nature of these spaces has led to standards that require the live monitoring of room pressure differentials, including USP 797 – Pharmaceutical Compounding- Sterile Preparations, USP 800 – Hazardous Drugs - Handling in Healthcare Settings and ASHRAE 170 – Ventilation of Healthcare Facilities.

Room pressure monitors can be used to monitor and provide indication of both a positive or negative pressure relationship between two spaces. The direction of airflow is determined by the application of the space, examples of which are detailed in the article.

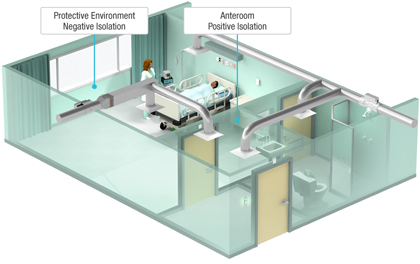

As defined in ASHRAE 170, an airborne infectious isolation (AII) room is designed with the patient space negatively pressurized relative to the corridor to ensure building occupants outside the room are safe from contamination. In the same manner, a protective environment (PE) room is positively pressurized relative to the corridor to ensure that contaminants are kept out of the patient space.

A combination (AII/PE) room consists of a negatively pressurized patient room relative to the anteroom and a positively pressurized anteroom relative to the corridor as shown in Figure 1. All three isolation room designs require a permanently installed device that monitors the differential pressure.

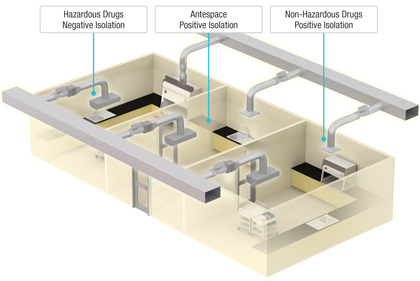

Another application for a room pressure monitor is a compounding pharmacy. Figure 2 shows a typical compounding pharmacy layout that works with both Hazardous and Non Hazardous Drugs (as defined by USP 797). This type of pharmacy is required to have continuous monitoring between the antespace and each of the buffer spaces, as well as the antespace and the corridor. A sterile pharmacy includes both positive and negative isolation spaces to suit compounding needs with a biosafety cabinet (BSC) in the negative room and a laminar airflow workbench (LAFW) in the positive room.

This sterile pharmacy can provide visual pressure indication in several ways, but each of them requires three pressure sensors. The designer of this space has the option to place the pressure sensors in one of two arrangements. The first design is shown in Figure 2 with the sensors installed above each doorway. This layout compares the buffer spaces to the antespace to monitor if the airflow is flowing correctly into or out of each buffer space. The three visual indicators would typically be installed beside each doorway to provide occupants with easy visibility of the pressure read-out.

The other option for pressure sensor placement would have each buffer space and the antespace measure differential directly to the corridor. This allows the occupants to see an absolute pressure difference for each space, rather than a relative difference comparing to the antespace and the ability to have a single user interface in the corridor.

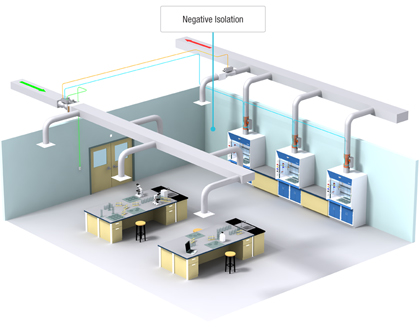

Figure 3 shows a typical fume hood laboratory with three hoods and multiple work stations. The primary source of airflow containment in this laboratory is the variable volume fume hoods. These exhaust hoods ensure that toxic chemicals or pathogens do not enter the work space.

As a secondary source of containment, the laboratory will typically be negatively pressurized and this pressurization helps to ensure that any contaminants from spills outside the fume hoods will be contained within the lab.

A room pressure monitor can be used to measure the differential pressure and provide occupants with local status indication of the pressure relationship. Only Biosafety Laboratories (BSL) Level 3 and 4 laboratories require a room pressure monitoring as per the Center for Disease Controls and Prevention (CDC) guidelines.

There are many other applications that require differential pressure relationships where room pressure monitors can provide a simple cost effective solution. Real-time monitoring eliminates the need for manual testing using tissue or smoke testing and gives peace of mind knowing the facility is prepared for times when the room becomes compromised.

For more information on room pressure monitoring please visit pricecriticalcontrols.com.