Volume 22 (September 2016)

FEATURED ARTICLE:

WHEN TO USE ACTIVE AND PASSIVE BEAMS

Adapted from the Price Engineer’s HVAC Handbook

Management of heat loads can generally be classified into two different types: all-air systems or hybrid systems. All-air systems have been the most prominent in North America during the 20th century and have been in use since the advent of air conditioning. These systems use air to service both the ventilation requirement as well as the building cooling loads. In general, these systems have a central air handling unit that delivers enough cool or warm air to satisfy the building load. Diffusers mounted in the zone deliver this air in such a way as to promote comfort and evenly distribute the air. In many cases, the amount of air required to cool or warm the space or the fluctuations of loads make designing in accordance to these principles difficult.

Hybrid systems combine an air-side ventilation system and a hydronic (or water-side) system. The air-side system is designed to meet all of the ventilation requirements for the building as well as satisfy the latent loads. It is typically a 100% outside air system and because the primary function of the supply air system is ventilation and dehumidification as opposed to sensible cooling it can be supplied at higher supply air temperatures than is typical of traditional mixing air distribution systems. The waterside system is designed to meet the balance of the sensible cooling and heating loads. These loads are handled by water-based products, such as active and passive beams, which transfer heat to the zone by induction.

ACTIVE AND PASSIVE BEAM CONCEPTS AND BENEFITS

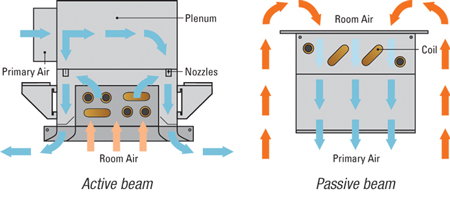

Active and passive beam systems provide an effective method for providing heating or cooling to a space while promoting a high level of occupant comfort and energy efficiency. There are two distinct system design philosophies that are considered when applying hydronic heating and/or cooling:

- Hydronic heating or cooling where the hydronic systems are integrated with the primary ventilation system. These are active beam systems.

- Hybrid heating or cooling systems where water-based devices are used in conjunction with a scaled-down ventilation system, and manage the bulk of the sensible cooling load. These systems generally use passive beams.

Benefits of Air-Water Systems

There are many benefits to heating and cooling using active or passive beams. Advantages of water-based heating and cooling systems over other mechanical systems include:

- Energy and system efficiency

- Reduced system horse power

- Improved indoor environmental quality

- Improved indoor air quality

- Increased thermal comfort

- Reduced mechanical footprint

- Lower maintenance costs

- Improved system hygiene

Active or passive beam systems are a good choice where:

- Thermal comfort is a major design consideration

- Areas with high sensible loads exist/ are present

- Areas requiring a high indoor air quality (100% outdoor air system) exist/are present

- Energy conservation is desired

ACTIVE AND PASSIVE BEAM APPLICATIONS

Active and passive beam systems are well-suited to some applications and less so to others. As a result, each application must be reviewed for potential benefits as well as the suitability of these types of systems.

One consideration which can assist in the decision to employ hydronic systems as opposed to an all-air system is the air-side load fraction, or the percentage of the total air supply which must be delivered to the zone to satisfy code and dehumidification requirements.

Table 1 shows the load fraction for several spaces. In the table the best applications for hydronic systems are those with the lowest air-side load fraction as they are the ones that will benefit the most from the efficiencies of hydronic systems by moving as much of the sensible load from the air side to hydronics.

Table 1: Typical load fractions for several spaces in the United States

Another factor which should be examined is the sensible heat ratio or the percentage of the cooling load which is sensible as opposed to latent.

The latent loads must be satisfied with an air system and offer some sensible cooling at the same time due to the temperature of dehumidified air. If the total sensible cooling load is significantly higher than the capacity of the air supplied to satisfy the latent or ventilation loads, a beam system might be a good choice.

Commercial Office BuildingsIn an office building, active and passive beam systems provide several benefits.

The lower supply air volume of the air handling system provides significant energy savings. In addition, the smaller infrastructure required to move this lower air flow allows for small plenum spaces, translating into shorter floor-to-floor construction or higher ceilings and potentially leading to a reduction in infrastructure and material costs.

The lower supply air volume and elimination of fans at or near the space offers a significant reduction in generated noise. The lower air flow often translates to reheat requirements being reduced.

In the case of 100% outside air systems, the lighting load captured in the return plenum is exhausted from the building, lowering the overall cooling load.

SchoolsSchools are another application that can benefit greatly from active and passive beam systems.

Similar to office buildings, the benefits of a lower supply air volume to the space are lower fan power, shorter plenum height, reduced reheat requirements and lower noise levels (often a critical design parameter of schools).

Hospital Patient RoomsHospitals are unique applications in that the supply air volume required by local codes for each space is often greater than the requirement of the cooling and heating load. In some jurisdictions, local code requires these higher air-change rates for all-air systems only. In these cases, the total air-change rate required is reduced if supplemental heating or cooling is used. This allows for a significant reduction in system air volume and yields energy savings and other benefits.

Furthermore, because these systems are generally constant air volume with the potential to reduce the primary air-change rates, reheat and the cooling energy discarded as part of the reheat process is a significant energy savings opportunity.

Depending on the application, a 100% outside air system may be used. These systems utilize no return air and therefore no mixing of return air between patient rooms occurs, potentially lowering the risk of hospital associated infections.

LaboratoriesIn load driven laboratories where the supply air rate is driven by the internal gains (such as refrigerators, testing equipment, etc.) as opposed to the exhaust requirements, active and passive beam systems can offer significant energy savings.

In these environments it is not unusual to require a large air-change rate in order to satisfy the load, although significantly less may be required by code (ASHRAE, 2008; CSA, 2010).

In these applications, the sensible loads can be handled by the supply air volume and decoupled from the makeup air required for the fume hood, providing an opportunity for energy savings.

These savings are typically due to the reduction in fan power as well as the energy associated with treating the outside air, which, in the case of a load driven lab, may be significant.

Hotels / DormsHotels, motels, dormitories and similar type buildings can also benefit from active and passive beam systems.

Fan power savings often come from the elimination of fan coil units located in the occupied space. The energy savings associated with these “local” fans is similar in magnitude to that of larger air handling systems. It also allows for the elimination of the electrical service required for the installation of fan coil units, as well as a reduction in the maintenance of the drain and filter systems.

The removal of these fans from the occupied space also provides lower noise levels, which can be a significant benefit in sleep areas.

LimitationsThere are several areas in a building where humidity can be difficult to control, such as lobby areas and locations of egress. These areas may see a significant short term humidity load if the entrances are not isolated in some way (revolving doors or vestibules). In these areas, a choice of complementary technology such as high performance fan coils can handle the latent loads in areas of egress using the supply water temperature of chilled beams.

Other applications may have high air flow/ventilation requirements, such as an exhaust driven lab. The majority of the benefit provided by the hydronic system is linked to the reduction in supply air flow.

As such, these applications requiring high airflows may not see sufficient benefit to justify the addition of the hydronic circulation systems, making them not likely to be a good candidate for this technology.

To learn more about leveraging the benefits of beams in your next project, please contact Beamteam@priceindustries.com.