FEATURED ARTICLE:

HIGH EFFECTIVENESS ENERGY RECOVERY

November 2017, Volume 24

By Mike Davey - Manager of Engineering and Business Development - Price Mechanical DOWNLOAD ARTICLE

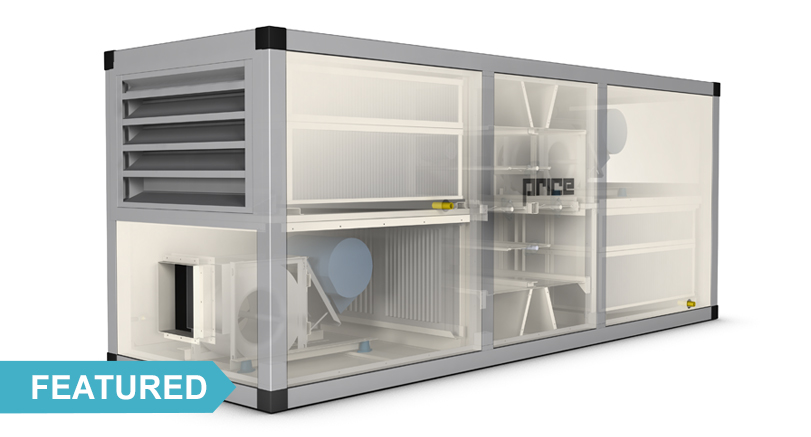

The energy recovery unit recovers sensible and latent energy during both heating and cooling seasons

Energy recovery options have increased beyond traditional wheels, plates and heat pipes. With purpose built engineering and component selection, a regenerating core can be capable of up to 90% effectiveness.

The energy recovery unit recovers sensible and latent energy during both heating and cooling seasons. This new regenerating core product sets itself apart from other recovery devices with its fully tested design, industry-leading effectiveness and no pre-heat requirement down to outdoor temperatures of -40°C/F. It takes the place of an energy wheel while offering superior energy savings and equipment payback.

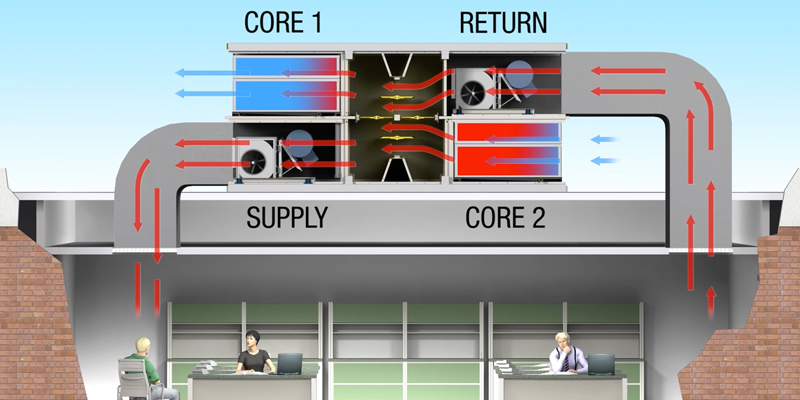

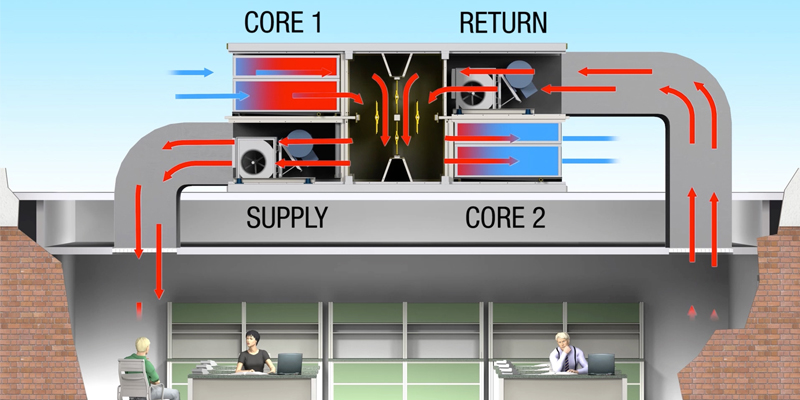

The center damper section couples a set of four dampers with a factory-installed controller to enable energy recovery, economizer, recirculation and standby modes. The key to the effectiveness of the recovery process is the two-cycle energy recovery mode.

- In Cycle A, Core 1 stores heat from the return air being exhausted from a building while Core 2 releases the heat previously stored to condition the colder outdoor air to supply air (representing winter operation).

- In Cycle B, the dampers are repositioned so that the inverse occurs: Core 1 releases heat that it captured and stored during Cycle A while Core 2 recovers heat from the exhaust air.

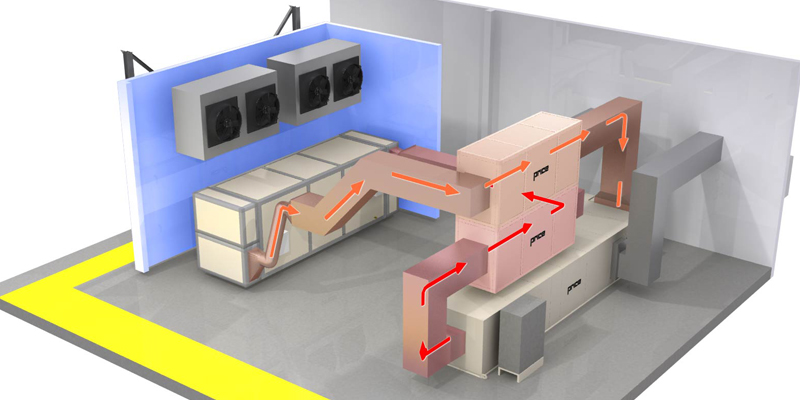

The Price Environmental Chamber at Price’s Egesz facility in Winnipeg, MB was designed and constructed to test product in accordance with ASHRAE 84, CSA C439, ISO 16494 and AHRI 1060 requirements while maintaining ambient temperatures ranging from -40°C to +40°C (-40°F to +104°F).

The Price Environmental Chamber and its custom designed cooling system are connected to a Price Mechanical custom air handling unit, which simulates building return air by heating or cooling and introducing humidity

The Price Environmental Chamber is capable of testing products to meet ASHRAE 84, CSA C439, ISO 16494 and AHRI 1060 requirements while maintaining temperatures ranging from -40°C to +40°C (-40°F to +104°F)

The chamber and its custom-designed cooling system are connected to a Price Mechanical custom air handling unit, which simulates building return air by heating or cooling and introducing humidity. Two Price nozzle banks meet ASHRAE Standard 41.2 to accurately measure both supply and return airflows on PRC units. NIST-certified temperature, humidity and pressure sensors are strategically positioned throughout the chamber and ducting, ensuring that all variables are accurately captured and logged.

“At Price, when we enter a new product category, it always starts with a major investment in world-class lab and testing facilities,” said Joe Cyr. “You simply must get the engineering and science right, without compromise or shortcuts. We’ve done just that, making a large upfront investment in an industry-leading lab with our environmental chamber. This, coupled with an expert team of dedicated engineers, and the rest of the 29,000 sq. ft. Price Research Center North, ensures that we will have the highest performing product in the market!”

To learn more about energy recovery unit design, testing and availability, please contact your local Mechanical representative.